Watch the video or use the instructions below

Also available on YouTube

Set up

Check your parts

Check you have all the major parts.

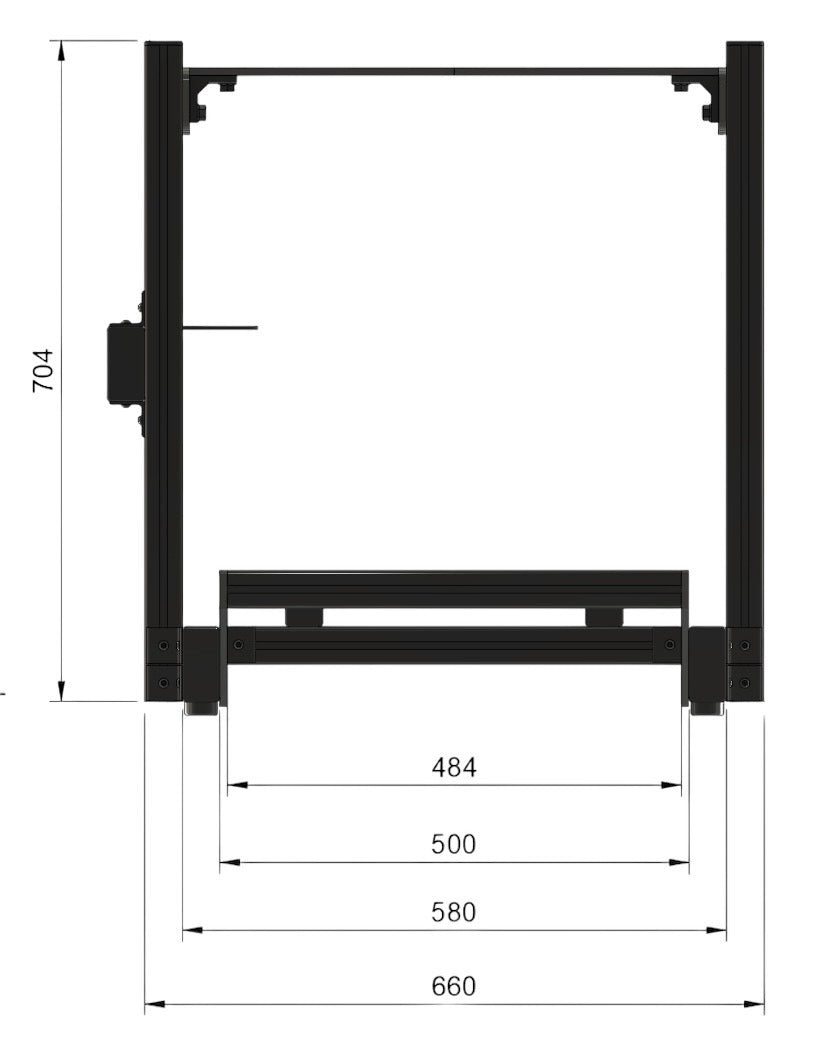

4x 4080 700mm

2x 4080 600mm

2x 4080 484mm

2x 4040 500mm

1x 4040 484mm

2x 4040 400mm

23x L bracket connector set

4x large brackets

6x universal brackets

1x Allen key set

1x spanner

1x spirit level

Notes

Before starting

The profiles are anodised aluminium. They can be scratched without careful assembly; however, if there does appear to be a scratch, most of the time they can be rubbed off with your fingers.

Notes

Use the 3D model, images, and drawings on the product page to check how the rig should look.

The final image on the product page is a 3D model that can be viewed on the majority of phones, tablets, and computers.

Notes

The L brackets with caps may need the tabs broken off for some accessory mounting.

These can be easily snapped off with leverage from a flat-head screwdriver.

Notes

Be careful with the edges of the aluminium profile as they are sharp and can damage floors with the weight of the seat.

The Seat

Assembling the seat

Skip this part if you don’t have a seat ready yet. Keep the 400mm pieces aside to attach to the bottom of the sliders, like in the picture.

The Seat

Start by attaching the shortest 4040, 400mm, to the sliders.

The Seat

You will need to manually move the slider to allow access to bolt them down.

Push down hard because the sliders can be hard to move.

The Seat

Attach the slider section to the bottom of the seat. This will require manually moving the slider again.

The Seat

Wedge the slider lever between the two sliders once they are securely attached to the seat. This will require a large amount of force to bend the bar so that it can be attached to the sliders.

The Build

The best position for lengthwise connectors (orange dots).

The Build

Use the long slotted connectors to join the one 4080 600mm to a 4080 700mm.

Leave the outside two channels open. The other channels can be filled with these connectors. This is because we will need the outside empty at a later stage.

See the previous image for where to put them.

Lengthwise profile connectors are only used at this step, so make sure to use all the ones you have.

The build

Attach all the feet to the bottom of the 1300mm piece (built from 600mm + 700mm).

The build

Connect the two long 1300mm pieces (these are the horizontal rails) with a 4080 500mm and capped brackets.

The build

Connect another 4040 500mm piece between the two horizontal rails with capped brackets. Tighten these finger-tight.

The build

Make sure to space these out approximately the length of the profiles for the bottom of the seat. They are the shortest, 400mm long.

Pedal plates

To build the pedal plate, start with planning how the pedals will connect. If it’s possible, connect the rear bolts of the pedals directly to the profile.

See some examples of different configurations below.

Always place the front bolts as close to the profiles as possible for maximum rigidity.

Pedal plates

The 484mm long pieces that go between the pedal plates will have a thread in the end, as highlighted in the photo.

The handbrake bar can also be put on the pedal area. You will only need two of the three pieces with threads to complete the pedal assembly.

Pedal plates

Note you can mix and match 484mm length between handbrake support and pedal supports.

If the pedals are too high, the whole assembly can be inverted as shown in this image.

Pedal plates

Add the lever bolts with washers to the pedal plate as shown.

Sometimes the profile gets in the way of turning the lever bolts. The head of the lever bolt can be pulled back to turn the bolt without turning the lever head.

Alternatively, the kit includes a standard bolt that can be used instead.

Pedal plates

Example of Fanatec pedals with pedal bar.

Pedal plates

Example of a standard pedal assembly for Fanatec, Moza, Simagic without pedals.

Pedal plates

Once the pedal plate is built, the safe assembly method is to disassemble and build the plate up directly, attaching the sides to the horizontal rails. Alternatively, the entire assembly can slide in from the back and along the slots.

Now that the pedal plate is on the rig, go back and tighten all the bolts in the seat area.

Pedal plates

Example of how to build a standard pedal plate with the Fanatec CSL / Moza CRP pedals.

The build

Pre-assemble nuts and bolts into eight of the aluminium L-shape brackets and slide them into position along the outside of the frame. Slide them along in a lifted position to prevent scratches on the outside.

The build

Position the gap between the brackets approximately 600mm from the open end of the frame without the cross connectors.

The Australian steel plate should be approximately 100mm closer to the driver (700mm form the open end).

The build

Use the spirit level on top of the upright to make sure it’s vertical and not leaning over, then tighten the bolts to lock in the position.

Try to align the two uprights as close as possible by using the joint in the horizontal bars as a reference.

The build

Slide / drop a 4080 700mm into each side. Keep everything loose to allow you to slide one bolt at a time into the bottom.

Steel top plate

If you have the steel top plate attached with T nuts and bolts, then use the orange markers / supports to drop it into place.

Steel top plate

Fasten the plate into position so it doesn’t fall. Remove the orange markers, then loosen the top plate and slide it down the uprights to rest on the orange markers.

The markers allow you to rest the steel top plate while you use your tools to connect it in place.

Slide it evenly (keep it level) down the uprights as it can scratch.

Aluminium top plate

Attach heavy-duty brackets to the top plate supports.

Aluminium top plate

Slide / drop the top plate supports onto the inside of the uprights.

The build

Bolt the top plate finger-tight to the top plate supports. This will hold the wheel in place while doing the test fit.

Test fit

Before tightening everything up, it’s time to do the first rough fit.

Test fit

The seat can be placed on top of the 500mm braces connecting the horizontal beams with the 400mm profiles connected to the bottom.

See correct bolt arrangement for the brackets below.

Test fit

The T-head bolt on the rig side can go straight into the slot.

The large nut on the seat side needs to be slid into the slot.

Slide these into the slots of the 400mm profiles connected to the bottom of the sliders. Then you can drop the seat onto the rig and the bolts will fit into the slot.

Test fit

Roughly check the distance from the seating position to where the wheel is where it’s expected to be.

This stage is not fine-tuning, just making sure it’s roughly in the right spot. Fine adjustment can be done by moving the pedals and top plate. You may need to move the upright to a better position depending on your body size and shape.

Test fit

Adjust the position of the components until an ergonomic seating position can be found.

The build

Attach three brackets to the handbrake support bar. This is the last piece of 4080 profile and should be 484mm, the same length as the pedal profiles.

The build

Slide the last remaining 484mm piece into this position.

Note: if you don’t want to use a handbrake, this part can be connected to the pedal assembly for extra support. Extra fasteners or brackets may be required.

The build

Use the universal brackets to attach your shifter, handbrake, and other accessories.

For best results, make sure the bolts are as close to the profile as possible or even connected directly to the profile.

The build

Add caps to all exposed aluminium profile faces. A firm push will get them mostly into place, and a few taps will finish them off.

The build

Fasten the wheelbase to the top plate and check fitment.

We recommend adjusting the seat and pedals before adjusting the wheelbase and top plate, as the top plate is the hardest to move.

If you are unsure which bolt holes to use, check out:

The build

To make fine adjustments, use the markers to provide temporary support and/or a way to remember the position of the top plate.

We recommend removing the wheelbase and top plate and following the above process for reassembly to minimise sliding in the slots and prevent scratches.

The build

Once you’re happy with the positions, go through and tighten everything back up.

After the first hour or two of racing, it’s good practice to tighten everything back up again as everything settles into position.

The build

Finally, mount any accessories and use the included cable management clips to route the cables inside the profiles.

The build

Accessories may need partial disassembly to fit, depending on your arrangement.

Use the included markers to remember the location of any parts you have taken off.

The build

Bracing

An extra brace may be used to strengthen the rig.

This is the best position for a brace.

L brackets may need the tabs broken off as shown earlier.